Manufacturing & Distribution Facilities Security Solutions

Protect Your Workforce and Assets Without Slowing Operations

Your employees should feel safe at work. Xtract One provides security that detects threats and prevents theft without creating bottlenecks during shift changes or slowing operational flow.

Real Results from Manufacturing & Distribution Facilities:

- High-volume screening during shift changes completed without entry delays

- Weapons detected without invasive searches or bag checks

- Asset protection at exits prevents theft of electronics and valuable components

- Security personnel redeployed from managing false alerts to addressing actual threats

Book Your

Site Assessment.

Different Solutions for Facility Needs

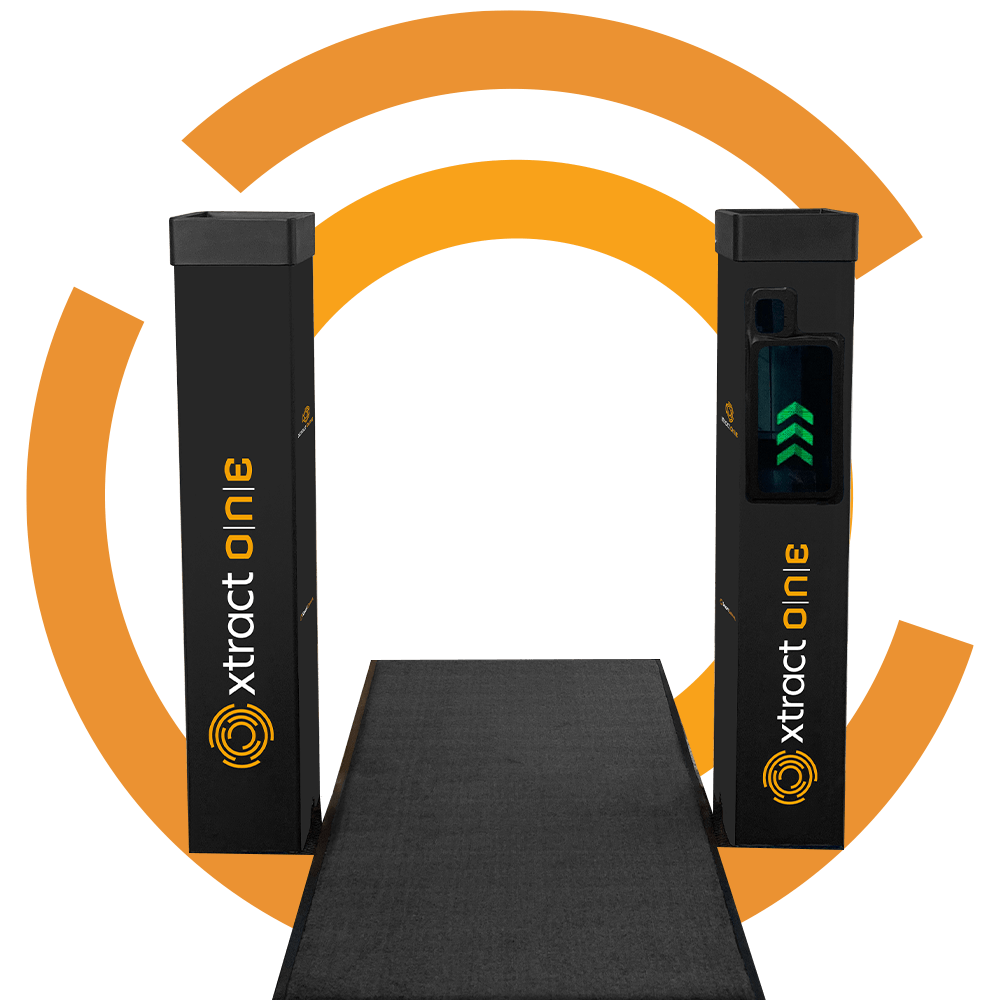

Xtract One Gateway for Employees Carrying Tools, Bags, and Equipment

Best when employees and visitors carry laptops, lunch containers, backpacks, or equipment.

- Screens everything together: Detects concealed weapons while ignoring authorized laptops and everyday items

- No bag separation required: Employees keep belongings with them, maintaining efficient flow

- Dual-direction capability: The only system that can be configured for both entry screening (weapons) and exit screening (asset protection)

- Prevents theft: Detects unauthorized removal of electronics, components, and valuable assets at exits

- No X-ray machines needed: Eliminates separate bag screening stations and minimizes footprint

- High throughput: Processes up to 3,000 individuals per hour at natural walking pace

- Ideal for: Distribution centers, manufacturing floors where employees carry bags and tools, facilities requiring theft prevention at exits

SmartGateway for Employee and Visitor Entry Points

Best for high-volume screening where individuals carry minimal personal items like phones, keys, wallets, and badges.

- Maximum threat detection: Detects both guns and small knives that other systems miss

- Quick processing: Handles shift changes without creating bottlenecks (up to 3,000 per hour)

- Natural flow: Employees walk through at normal pace without divesting personal items

- Unobtrusive screening: Maintains efficient operations without invasive procedures

- Flexible deployment: Mobile design can be repositioned across multiple access points

- Ideal for: Employee entrances, visitor checkpoints, administrative areas where individuals carry minimal belongings

Xtract One View for Fleet Operation

Manage security across multiple facilities or access points from one platform.

Real-time monitoring: See activity across all entry and exit points

Shift optimization: Review traffic patterns to improve security personnel deployment

Multi-site coordination: Centralized control for distributed operations

Remote management: Monitor and adjust systems from anywhere

Performance tracking: Incident reporting and operational analytics

What Your Facility Gains

Staff Safety

Workforce Protection

- Effective weapon detection at all entry points

- Discreet alerts allow security to respond before threats escalate

- Reduced workplace violence risk

- Protection for employees, contractors, and visitors

Staff Safety

Asset Security

- Exit screening detects unauthorized removal of electronics and valuable components

- Data-driven insights identify theft patterns and vulnerabilities

- Reduced inventory loss and shrinkage

- Protection of proprietary equipment and materials

Staff Safety

Operational Efficiency

- No bottlenecks during shift changes

- Employees maintain natural flow through entry and exit points

- Security staff can focus on genuine threats rather than false alarms

- Minimal disruption to production schedules

What Xtract One Provides

Protection during all shifts including overnight and weekend operations

Flexible systems that adapt to different facility layouts and operational requirements

Both ingress threat detection and egress asset protection

Ongoing support as your facility's needs change

Support and Training

Our team works directly with facility security directors and operations managers to understand your specific requirements.

We provide initial site assessments to understand your entry points, exit points, shift schedules, what employees carry, and asset protection concerns.

Once the right solution is determined, we train your security personnel on effective operation and system management.

Ongoing support ensures your security approach adapts as your operations grow and security challenges change.

Lifetime access to technical support means you always have expert guidance available.

Trusted by Industrial Operations

Protecting major manufacturing facilities and distribution centers across North America

Selected by Fortune 500 companies seeking both threat detection and asset protection

Deployed across automotive, electronics, logistics, and industrial manufacturing operations

Trusted by facilities prioritizing employee safety and inventory security

Ready to Protect Your Facility?

Book your site assessment today to learn how Xtract One can provide security without slowing your operations.

Frequently Asked Questions (FAQs)

Manufacturing facilities and distribution centers face unique security requirements that traditional metal detectors cannot adequately address. Employee entrances, visitor checkpoints, and loading dock access points serve workers carrying lunch containers, laptops, phones, keys, and equipment that trigger constant alerts on walk-through metal detectors.

This creates a choice between security and operational efficiency. Security personnel either spend excessive time manually screening each alert during critical shift changes, or they begin ignoring alerts altogether, defeating the purpose of security screening.

Modern AI-powered weapons detection solves this problem. These systems distinguish between everyday items like laptops, lunch boxes, and authorized equipment from actual threats. Employees and visitors move through screening at a natural walking pace without divesting personal belongings or creating bottlenecks during shift changes.

The result is effective security screening that doesn’t compromise operational flow or create delays at entry points. Security personnel can focus on genuine threats rather than managing screening queues, while facilities maintain protection from workplace violence and the ability to prevent asset theft at exit points.

| Capability | Xtract One Gateway | SmartGateway | Walk Through Metal Detectors |

|---|---|---|---|

| Divestment Required | No divestment. Individuals walk through with bags, lunch containers, phones, keys, and equipment | No divestment. Employees walk through with phones, keys, wallets, and badges | Yes. Pockets must be emptied, bags removed, equipment may trigger alerts |

| Accuracy with Personal Items | Detects threats while ignoring authorized tools, laptops, equipment, and everyday work items | Detects threats while ignoring phones, keys, badges, and personal items | Frequent alerts from everyday items create screening delays and false alarms |

| Throughput / Wait Time | Up to 3,000 individuals per hour at natural walking pace | Up to 3,000 individuals per hour at natural walking pace | 200-400 individuals per hour with frequent stops for manual checks |

| Shift Change Experience | Processes high volumes during shift changes without creating entry bottlenecks | Processes high volumes during shift changes without creating entry bottlenecks | Creates significant delays during shift changes when hundreds arrive simultaneously |

| Exit/Egress Screening | Can be configured for asset protection at exits. Detects unauthorized removal of electronics, components, and valuable inventory | Not designed for egress screening | Not designed for egress screening. Separate systems required for theft prevention |

| Analytics / Reporting | Real-time analytics via Xtract One View with customizable reports and multi-site oversight | Real-time analytics via Xtract One View with customizable reports and multi-site oversight | Manual logging only. No digital tracking or operational insights |

| Bag Screening | Scans bags while worn or carried. No separate screening required | Individuals walk through freely. Bags typically remain outside scanning area | Separate bag check or X-ray required, creating bottlenecks |

A weapons detection system for manufacturing facilities screens employees and visitors entering industrial operations for concealed weapons while allowing equipment, lunch containers, and personal belongings to pass through without alerts. These systems use AI-powered detection to identify genuine threats rather than simply responding to any metal object.

Modern weapons detection systems for manufacturing and distribution facilities process employees at natural walking speeds without requiring divestment of bags or pockets. This maintains operational flow during critical shift changes while providing security personnel with accurate threat information for workplace violence prevention.

Walk-through metal detectors alert on any metal object, creating constant interruptions when employees arrive with lunch containers, equipment, phones, keys, and work gear. Security teams must manually check each alert, creating bottlenecks during shift changes when hundreds of employees arrive simultaneously.

Xtract One’s AI-powered weapons detection distinguishes between threatening items and everyday work items. The system identifies concealed weapons while ignoring authorized laptops, equipment, and personal belongings that employees routinely carry.

Xtract One Gateway screens both the individual and their carried bags simultaneously, eliminating the need for separate bag checks or X-ray machines. SmartGateway processes individuals at a natural walking pace without divestment requirements. Both systems provide security screening without disrupting shift changes or creating the delays associated with traditional metal detectors.

Xtract One systems process up to 3,000 individuals per hour while walk-through metal detectors typically handle 200-400 individuals per hour due to frequent alerts and manual screening requirements.

Facilities maintain continuous operational flow during shift changes because employees walk through at their natural pace without stopping to empty pockets or open bags. There are no bottlenecks from false alerts on work equipment or everyday items.

Security interventions occur only when the system detects actual threats. Your team focuses on genuine security concerns rather than managing queues or manually checking routine alerts from lunch boxes, and authorized equipment.

Xtract One Gateway is the only weapons detection system that can be configured for egress screening at exit points. The system detects unauthorized removal of electronics, components, inventory, and valuable assets as employees leave the facility.

Exit screening operates at the same high throughput as entry screening. Employees walk through at natural pace while the system identifies prohibited items being removed from the facility. Security receives alerts only when the system detects unauthorized assets, not on personal belongings employees are permitted to carry out.

This dual-direction capability allows facilities to address both workplace violence threats at entry and inventory protection at exits using a single technology platform, eliminating the need for separate theft prevention systems.

Xtract One systems operate 24/7/365 without daily calibration requirements or performance degradation. The systems function identically across all shifts, providing consistent security coverage during day, evening, and overnight operations.

Xtract One View provides centralized monitoring across all shifts and multiple facilities. Security supervisors can review screening activity, compare data between shifts, and identify patterns that may indicate security concerns or operational issues.

The systems require no manual adjustments between shifts and no technical expertise to operate during low-staffing overnight periods. Remote support is available around the clock whenever questions arise.

Xtract One View provides centralized management for multi-site manufacturing and distribution operations. Monitor all facilities from a single platform, review traffic patterns across locations, and manage system settings remotely.

The cloud-based platform allows security directors to oversee multiple sites, compare operational data between facilities, and ensure consistent security standards across your organization. Access controls allow different permission levels for site-specific security staff and enterprise-wide administrators.

System updates deploy automatically to all locations, ensuring every facility benefits from the latest AI improvements and security enhancements without requiring on-site technical support.

Xtract One systems detect firearms, knives, and other prohibited weapons carried on the body or within bags and personal belongings. The AI-powered detection classifies the type of threat object and identifies its location without alerting on everyday work items.

Gun detectors within the Xtract One Gateway system recognize various firearm types while distinguishing them from laptops, tablets, equipment, and authorized work gear. Weapons detection systems identify genuine threats without the constant false alerts that occur with traditional metal detectors when employees carry work equipment.

Detection settings can be customized for your facility’s specific security requirements. The systems adapt to different threat profiles while maintaining accuracy in environments where employees routinely carry equipment and personal belongings.

Contact our team at sales@xtractone.com for a site evaluation. We assess your facility’s entry points, exit points, shift schedules, employee flow patterns, and specific security requirements to recommend the appropriate configuration.

Our implementation process includes equipment installation, security personnel training, and integration with your existing security protocols. The Xtract One team provides ongoing support and software updates to ensure your security solutions remain effective.

You’ll have access to Xtract One View for centralized management across multiple facilities and real-time operational insights. Our customer success team remains available to optimize your system configuration as your operation’s needs change.